Running Replenishment across multiple companies is a common approach in international operations or for retailers with franchise partners.

Replenishment supports scenarios where purchase replenishment is performed in a central supply chain company (HQ) and the stores reside in sales companies. The sales companies are replenished from the supply chain company.

In this scenario the store is in full control of store replenishment while the HQ handles the purchase replenishment. The HQ company needs to have detailed information about stock and demand of the stores in the sales companies to calculate the purchases for the warehouse.

To achieve this, replenishment is run in the following steps:

Sales companies

- The Replenishment Item Quantity is calculated in each of the sales companies.

- With this, the sales company is equipped with the sales and demand information in the sales companies, enabling it to:

- calculate purchase orders (against the supply chain company).

Supply Chain company

- The Replenishment Item Quantity is calculated in the central supply chain company, and the pre-calculated Replenishment Item Quantity data from the sales companies is copied to the supply chain company.

The location names need to be in synch between the companies. - With this, the supply chain company is equipped with the sales and demand information in the sales company, enabling it to:

- calculate purchase orders (against vendors)

Since the sales company stores create the purchase orders, the HQ does not calculate any proposals to replenish the stores.

Key questions / considerations

Questions:

- Which companies are responsible for purchase?

(these are the supply chain companies) - Which companies are replenished from the supply chain companies?

(these are the sales companies) - Are the sales companies calculating replenishment by themselves and creating Purchase Orders against the supply chain company?

- Are all items in the sales companies replenished from the supply chain company?

- If not:

- What are the exceptions?

- Are those items needed in the supply chain company?

- How are those items purchased?

- Manual Purchase Orders?

- Replenishment in sales companies?

- If not:

- Who is responsible for data maintenance?

- If mixed responsibility:

- What data are maintained by the supply chain company?

- What data are maintained by the sales companies?

- If mixed responsibility:

- How are data replicated between the supply chain company and the sales companies?

Output

-

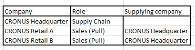

A company list which describes the dependencies:

-

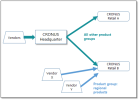

Topology drawing:

LS Central setup considerations

Company

LS Central and Replenishment need to be set up in all affected companies.

Locations in sales companies

In this scenario all store locations have to be set up to retrieve the demand information from the local company.

This is done by selecting the value Local Company in the field Data Source on the Location Card page.

For more information see Location.

Locations in HQ company

In this scenario all store locations need to be created in the HQ company, too, and be set up to retrieve the demand information from the sales company.

This is done by selecting the value Other Company in the field Data Source on the Location Card page.

Furthermore, the sales company name needs to be set up in the field Data Source Company.

A location with this setup will not calculate stock and demand in the current company, but copy the calculated values from the set up Data Source Company.

For more information see Location.

Replenishment Calculation

In this scenario the Replenishment calculation takes place in four steps:

- The Replenishment Item Quantity (RIQ) is calculated in the sales companies.

The RIQ is a snapshot of the current stock situation in the stores. - The Replenishment Journals for Purchase Orders are calculated in the sales companies.

- The Replenishment Item Quantity (RIQ) is calculated in the supply chain company (HQ).

The pre-calculated RIQ information from the sales companies is copied to the supply chain company. - The Replenishment Journals for Purchase Orders are calculated in the supply chain company.

It is necessary to ensure that the RIQ calculation in the sales companies is finished before the RIQ calculation starts in the supply chain company.

Steps 3 and 4 can run in parallel.

Intercompany transfer of Purchase Orders

The Intercompany transfer of the Purchase Orders from the sales companies to the HQ company is not part of Replenishment and has to be covered by standard Business Central functionality.

Master Data

Since the supply chain company is not in full charge of Replenishment, it needs to be decided which data (items, replenishment parameters) are maintained in which company. Usually, the items are maintained in the supply chain company but replenishment parameters might be maintained locally by the sales companies.

Data Replication Jobs need to be set up to replicate the data to the sales companies.

Go back to: